Startup WingWarp Raised Over $1 Million Aided by Nautilus 3D Printer

WingWarp is a San Francisco based software startup. Their platform functions as a digital cameraman. Using iPhones and a specialized software suite, youth sports teams can produce professional quality films of their games and share highlights in real time.

The Challenge

WingWarp wanted to be able to test different angles, spacing, and number of phones to develop hardware that customers could easily use to engage with their platform. Traditional manufacturing methods like Injection Molding and Machining posed very high costs for iterative design and testing.

2 iPhone holder in action

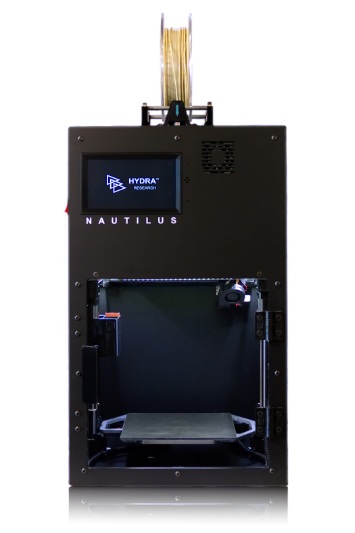

Enter the Nautilus by Hydra Research

WingWarp began by printing their prototypes in PLA, a commonly used 3D printing plastic, but found that the parts would break too easily so they began exploring other materials. With the guidance of Hydra Research they discovered Nylon CF15 by Fillamentum, a chopped carbon fiber reinforced nylon with high-impact resistance and exceptional layer bonding properties. Because of the Nautilus 3D Printer’s versatility and focus on engineering they were able to make this switch without any hardware modifications or accessories.

“For any company out there that might be wondering if 3D printing

fits their needs, the Hydra team can be a great resource and the

Nautilus printer has proven to be super high quality.”

The Results

Having a physical product for potential customers and investors to see and hold is often instrumental in convincing them that what you are doing is more than just an idea. The team at WingWarp experienced just that. They successfully raised over $1 million from Silicon Valley investors.

WingWarp has been using Hydra Research 3D printing, modeling, and consulting services for about 6 months now decided to purchase their own printer. WingWarp plans to launch their product and will get it in the hands of millions of people. They foresee many more hardware iterations and will be using the Nautilus 3D printer to do that.

Prototype 3 phone holder printed in Nylon CF15 (carbon fiber reinforced nylon)

“We didn’t have a ton of background in additive manufacturing. The Hydra team and Nautilus printer have been instrumental in helping us build many iterations of our prototype. We would not have been able to do this without their expertise and product. In addition to the printer itself, they go the extra mile to ensure their customers achieve success in terms of their 3D printing goals.

Our ability to rapidly prototype and test many different variations of hardware (printed on the Nautilus) to support our iOS software allowed us to user test and validate our product thesis leading to both investor success and also customer traction.”

All Photos unless otherwise noted © Wing Warp Inc.

*licensed under CC BY-SA 4.0 International by Hydra Research, LLC