Optimizing Part Orientation

The orientation with which you place your model on the print surface can have significant effects on the part’s physical and visual properties. FFF 3D printed parts do not have uniform part strength across all axes, the stacked layer process leads to diminished strength along the layer lines. Additionally, print orientation can affect the visual quality of certain features like curved surfaces and overhangs.

We will go over a few examples and ways to think about optimizing part orientation below. Keep in mind that in some cases you will have to choose between strength or visual quality. Finding the best orientation can be an art and more experience will hone your intuition on what the best orientation is for what you are trying to achieve.

Orient for Strength

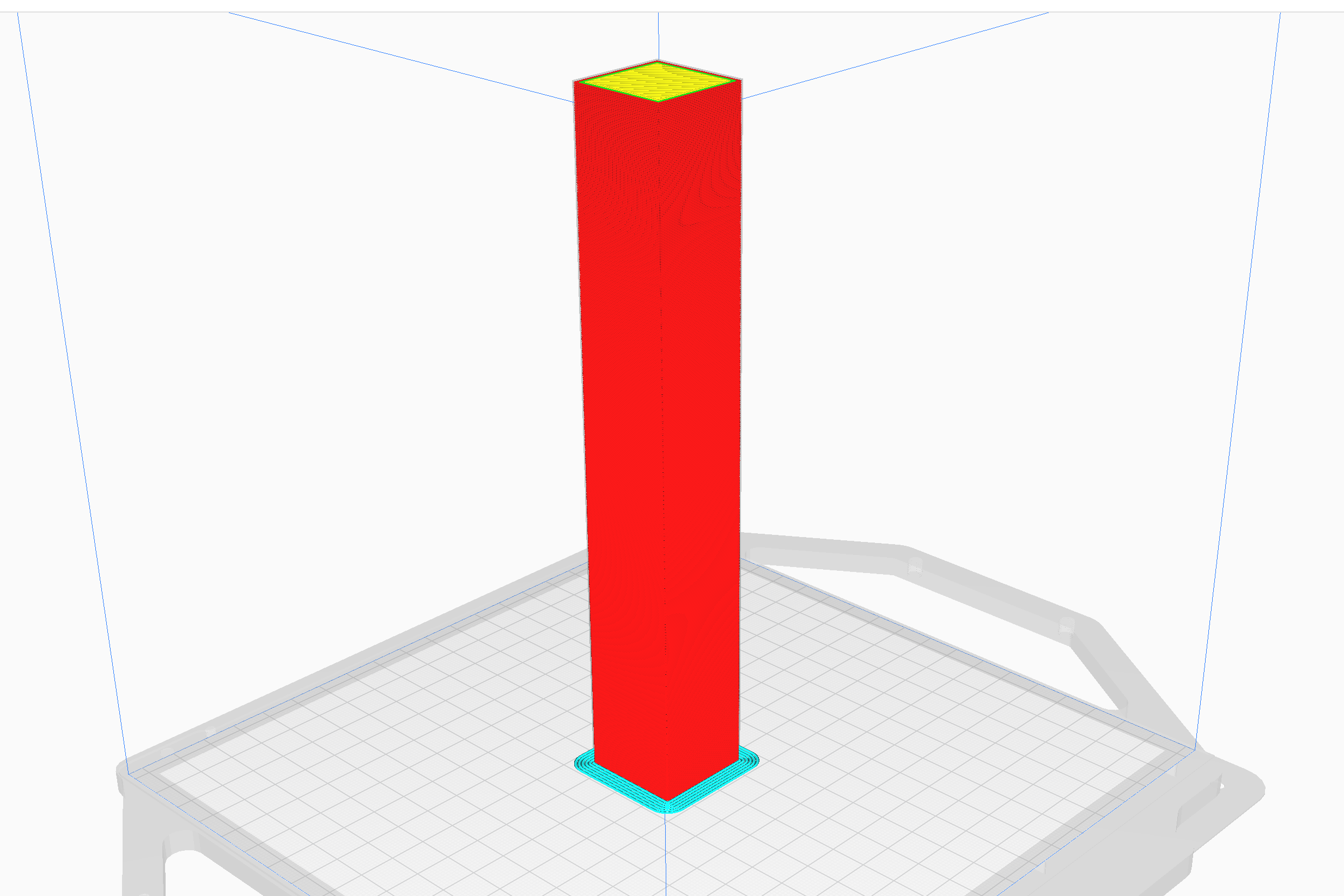

Orienting for part strength usually means setting up your print to have the layer lines in the longest direction of the part. Avoid printing thin parts vertically. In the example below, the part will be much easier to break if printed in the orientation shown on the right.

ⓘ Some materials with a high shrinkage rate when cooling will be more likely to warp if printed in the orientation shown on the left.

Oriented for maximum strength

Oriented for minimum strength

Orient for Visuals

This one can be the trickiest, especially with complicated part geometries. In general you want to try to avoid steep overhangs, downward facing rounded surfaces, embossed or engraved text on horizontal surfaces, and use of support material. Below is a very simple example to provide a visual to get you to begin thinking about options for the best orientation to promote visuals.

The angled surface will be smooth

The angled surface will have a stair step effect

The angled surface will droop and be rough, likely requiring support material

Orientation Compromises

Sometimes you can’t have your cake and eat it too. It is often the case, particularly with more complex geometries, that you will have to choose between an orientation that offers either the best strength or the best visual, but not both. In the example below the left orientation will yield the best strength, but the roundness of the rod will be affected by drooping and roughness on the bottom and stair stepping on the top. The orientation on the right will result in a much more smooth and round part, but it will be much easier to break due to the orientation of the layers.